How Much Does an OSHA Forklift Violation Cost?

The Occupational Safety and Health Administration, also known as OSHA, exists to ensure safe and healthy working conditions for workers by setting and enforcing standards and by providing training, outreach, education and assistance. Forklift operation falls within the scope of OSHA regulations, which means they can also be subject to violations and subsequent fees.

With almost 900,000 forklifts in operation in the US as of 2018, based on OSHA’s reporting of forklift related injuries, there’s about a 1 in 10 chance that each forklift will be involved in an accident in a given year. It’s important to understand OSHA’s regulations are put in place to prevent these accidents, and the costs associated with ignoring them.

The reality is that the true cost of an OSHA violation goes beyond just the OSHA penalty fees. These other costs include employee injury, time away from work, loss of productivity, machine repairs and much more. Keep reading to learn about some of the common OSHA violations and about the real cost to businesses who don’t follow OSHA’s regulations.

The Top 10 OSHA Violations

Here’s the list of top violations for October 1, 2019, to September 30, 2020:

- Fall Protection, construction (29 CFR 1926.501) [related OSHA Safety and Health Topics page]

- Hazard Communication Standard, general industry (29 CFR 1910.1200) [related OSHA Safety and Health Topics page]

- Respiratory Protection, general industry (29 CFR 1910.134) [related OSHA Safety and Health Topics page]

- Scaffolding, general requirements, construction (29 CFR 1926.451) [related OSHA Safety and Health Topics page]

- Ladders, construction (29 CFR 1926.1053) [related OSHA Safety and Health Topics page]

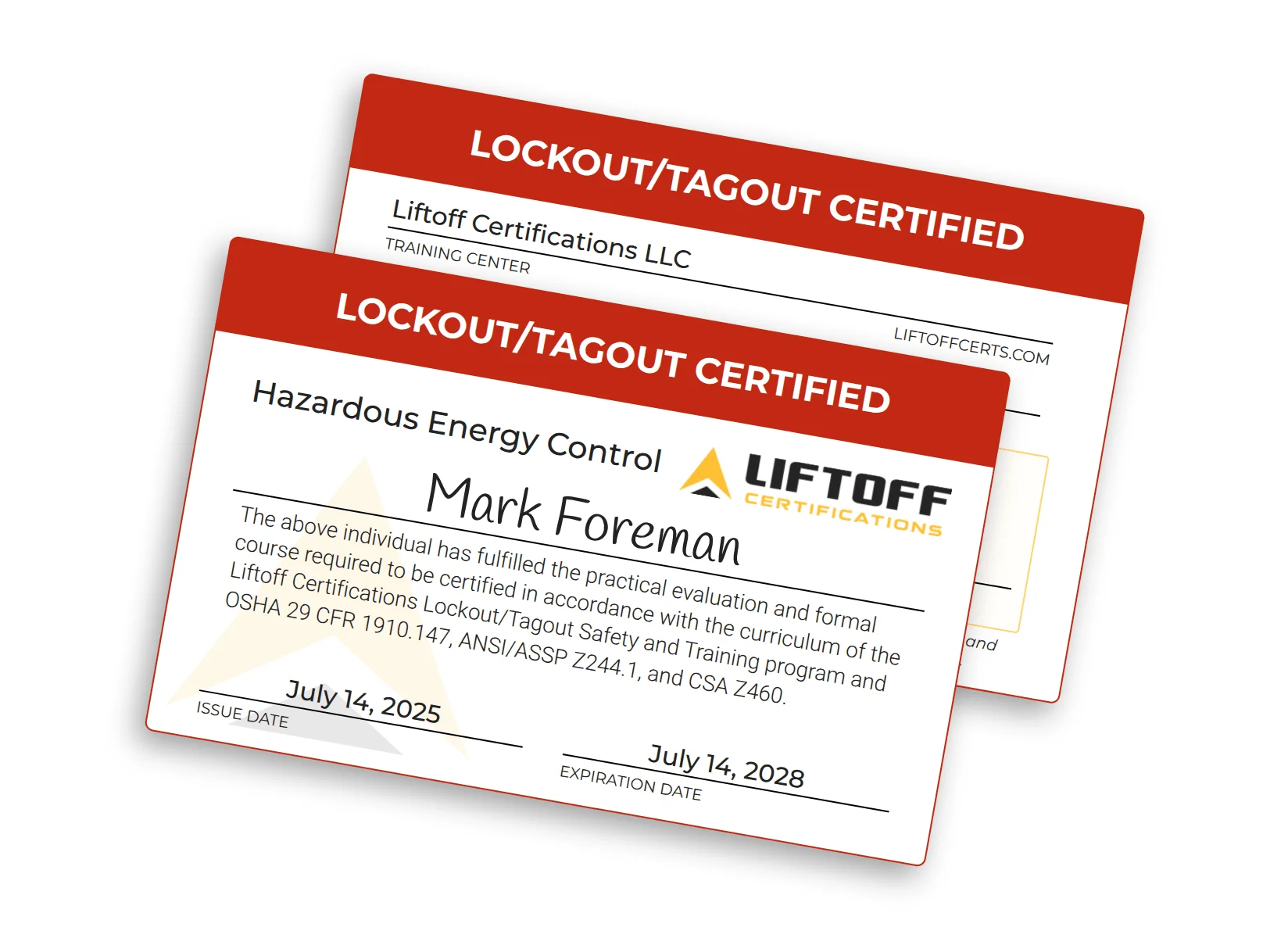

- Control of Hazardous Energy (lockout/tagout), general industry (29 CFR 1910.147) [related OSHA Safety and Health Topics page]

- Powered Industrial Trucks, general industry (29 CFR 1910.178) [related OSHA Safety and Health Topics page]

- Fall Protection–Training Requirements (29 CFR 1926.503) [related OSHA Safety and Health Topics page]

- Eye and Face Protection (29 CFR 1926.102) [related OSHA Safety and Health Topics page]

- Machinery and Machine Guarding, general requirements (29 CFR 1910.212) [related OSHA Safety and Health Topics page]

The Real Cost of an OSHA Forklift Violation

When it comes to the cost of an OSHA violation, it goes beyond just the monetary penalty from OSHA. The reality is that it will impact morale, productivity, loss of staff and much more. These are some of the main costs to consider.

OSHA Penalty

OSHA is very clear on their penalty structure for civil violations. While the single violations may be just a slight impact on your business, willful or repeated penalty fees could put some companies out of business. That’s why it’s imperative to make sure your teams receive proper safety and forklift training to keep people safe and your business profitable.

The main OSHA penalties are:

- Serious violations: Maximum penalty of $13,653, minimum penalty of $975

- Other-than-serious violations: Maximum penalty of $13,653, minimum of $0

- Willful or repeated: Maximum penalty of $135,532, minimum of $9,753

Employee Injury

When we look at a report of nonfatal forklift related accidents that occurred and involved days away from work, the numbers speak for themselves. Of the 8,140 forklift accidents that occurred in 2019 with days away from work, the median number of days away from work was 16, which is up from 14 in 2018. It’s important to note that 40% of those accidents involved 31+ days away from work.

Loss of Production Time

Whether an OSHA violation comes as a result of a surprise inspection, third party reporting or employee injury, it’s going to mean paperwork, going through the proper reporting channels, recovery time or retraining employees. All of these items take you and your team away from the most important thing which is productive time working on your business.

Employee Turnover

The cost of losing employees and having to rehire can not be understated. A recent study showed that the average cost of hiring a new employee is about $4,000. That means that if an employee is injured or doesn’t feel safe at work due to OSHA violations, you could be out a trained employee and have to find and train a new person to fill that spot.

Equipment Damage

While employee safety is the most important thing to keep in mind when it comes to OSHA regulations, the cost of repairing and replacing damaged equipment can’t be overlooked. A brand new, electric forklift costs $20,000 – $45,000+. Repairs range from a few hundred to a few thousand dollars and add up quickly when they’re unexpected. With proper forklift training, your team will maximize not only their safety but maintenance of the machines.

How Forklift Training Prevents OSHA Violations

When it comes to safety in the workplace, the reality is that accidents will happen. The hope is that businesses can prevent unnecessary accidents and potential violations in the workplace through proper forklift training and education. That’s why it’s incredibly important to find a certification that thoroughly covers all safety and operation materials for your team members.

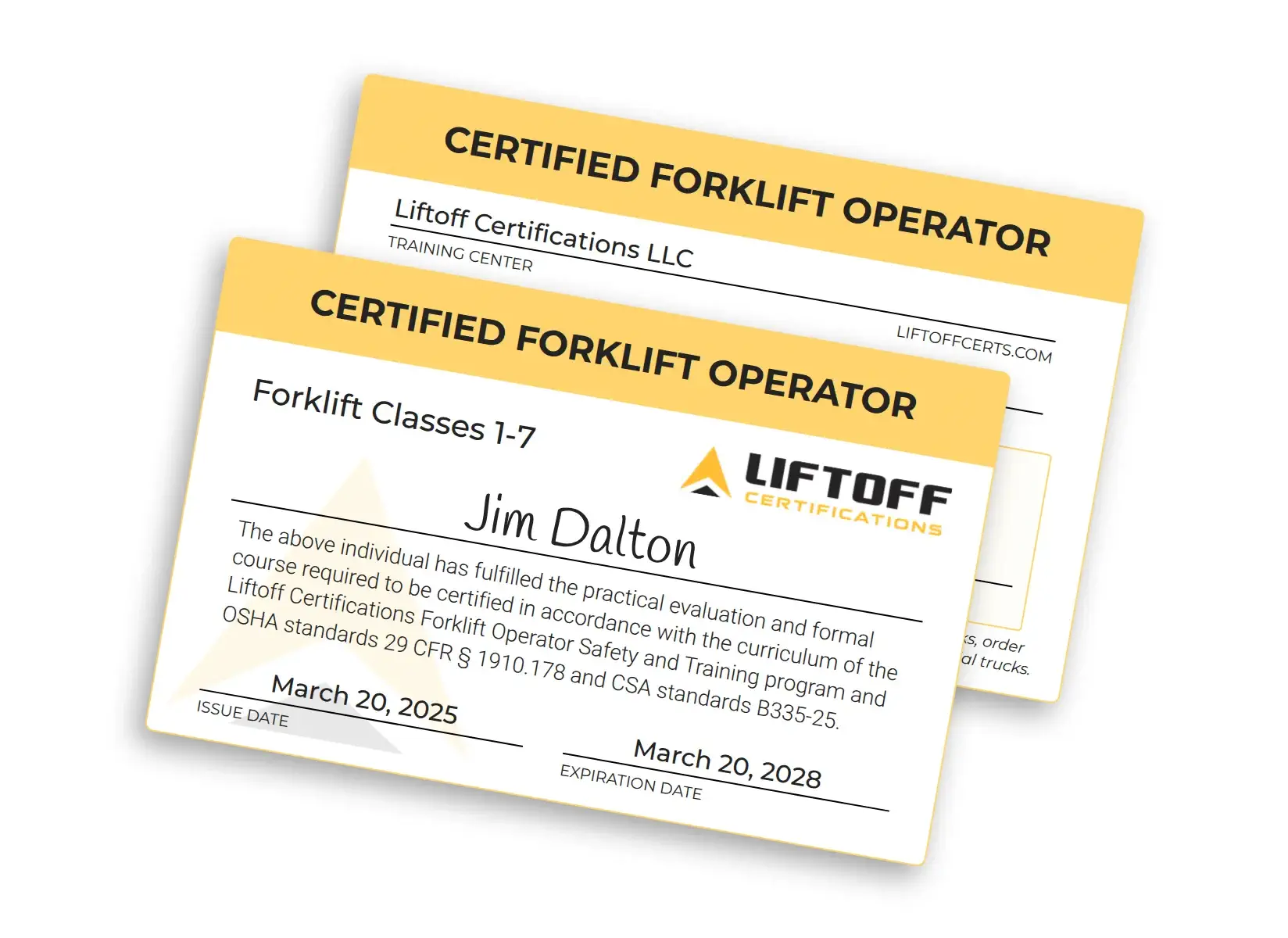

Liftoff Certifications is proud to have a 4.98-star rated training course that covers all the OSHA required materials and provides an extensive hands on training checklist for proper in-person education. The training covers topics from specific OSHA and safety regulations, safeguarding you against clear violations, as well as the more practical components of operating a forklift including how to load, drive, maintain and much more.

Get Forklift, MEWP & Fall Protection Certified Today with Liftoff Certifications

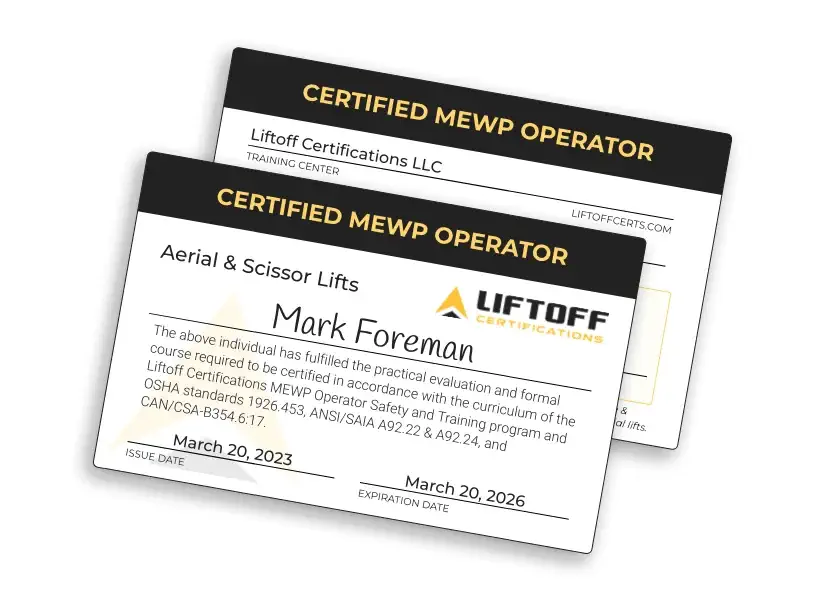

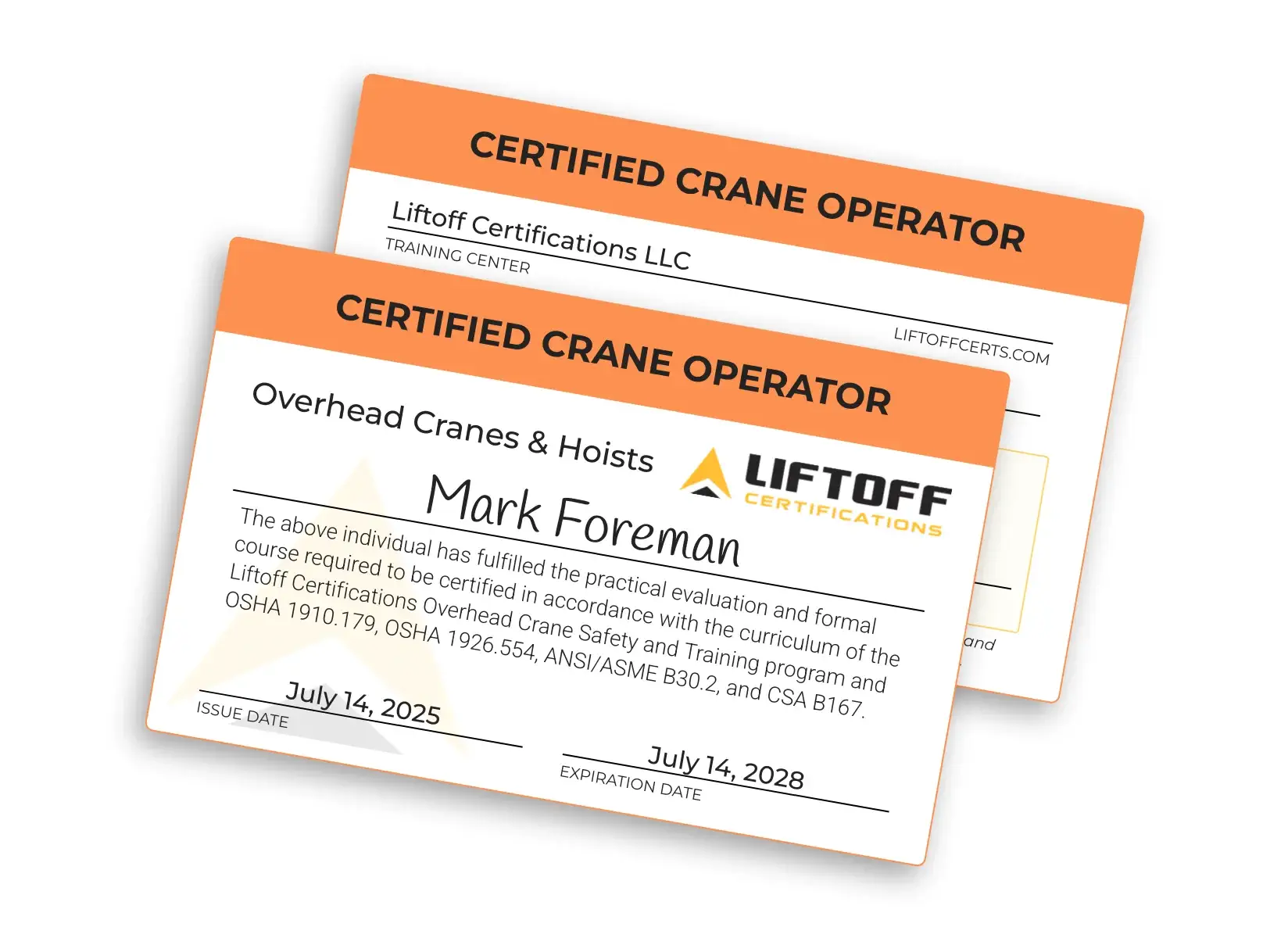

Liftoff Certifications offers some of the industry’s most affordable Forklift Operator, MEWP (Boom & Scissor Lift) Operator, and Fall Protection Certification and Recertification courses and is the gold standard for online OSHA training.

If you are ready to give an online forklift certification or recertification a try, get signed up today for our OSHA Forklift Operator Training.

For our MEWP (Boom & Scissor Lift) training, get signed up today for the OSHA MEWP Operator Training.

And for Fall Protection, get registered for by clicking here for the OSHA Fall Protection Training.

We’ve got you covered with a 100% money back guarantee and we guarantee national acceptance of our OSHA certification.