The Evolution of Forklift Technology: How New Advancements are Changing the Industry

Forklift technology has come a long way since its invention in the early 20th century. Today, new advancements in technology are transforming the industry in exciting ways. To understand how we go to where we are today, let’s take a look at how forklift technology changed throughout the 20th century:

From Invention to Implementation

The forklift was invented in the early 1900s as an alternative to manual labor for lifting and transporting heavy loads. The first forklifts were powered by steam engines and were used primarily in factories and warehouses.

Invention: The forklift was invented in the early 1900s as an alternative to manual labor for lifting and transporting heavy loads. The first forklifts were powered by steam engines and were used primarily in factories and warehouses.

Gasoline-powered engines: In the 1920s, gasoline-powered forklifts were introduced. These forklifts were more versatile and could be used both indoors and outdoors.

Electric-powered forklifts: In the 1930s, electric-powered forklifts were introduced. These forklifts were quieter and produced no emissions, making them ideal for indoor use.

Hydraulic lifting: In the 1940s, forklifts were equipped with hydraulic lifting systems, which made it easier to lift and transport heavy loads.

Diesel-powered forklifts: In the 1950s, diesel-powered forklifts were introduced. These forklifts were more powerful and could handle heavier loads.

Improved safety features: In the 1960s, forklifts were equipped with improved safety features, such as seat belts and roll bars, to protect operators in the event of an accident.

Narrow aisle forklifts: In the 1970s, narrow aisle forklifts were introduced. These forklifts were designed to maneuver in tight spaces and could lift loads to greater heights.

Computerized controls: In the 1980s, forklifts were equipped with computerized controls, which improved their precision and efficiency.

Ergonomic design: In the 1990s, forklifts were designed with ergonomics in mind, making them more comfortable and easier to operate.

These are just a few examples of how forklift technology evolved throughout the 20th century. As we move into the 21st century, new advancements in technology are transforming the industry in exciting ways, such as automation and robotics, alternative power sources, data analytics, telematics, and augmented reality. The forklift industry will continue to evolve and improve, making it safer, more efficient, and more productive for workers.

Let’s dive into those newer advancements that we’re seeing today and expect to see more of in the future.

Advancements in Forklift Technology

Here are some of the latest trends in forklift technology:

- Automation and Robotics: Automation is one of the biggest trends in forklift technology today. Automated forklifts use sensors and cameras to navigate warehouses and move materials without the need for a human operator. This technology is especially useful in large warehouses or distribution centers where there is a lot of repetitive material movement.

- Alternative Power Sources: Traditional forklifts run on gasoline or diesel, but there are now alternative power sources available. Electric forklifts are becoming increasingly popular due to their low noise levels, zero emissions, and lower maintenance costs. There are also forklifts that run on hydrogen fuel cells, which produce electricity through a chemical reaction between hydrogen and oxygen, emitting only water as a byproduct.

- Data Analytics: Forklifts are now equipped with sensors that can track everything from fuel consumption and tire pressure to operator behavior and material movement. This data can be used to optimize forklift usage, improve safety, and reduce costs. For example, data analytics can help identify areas where operators can improve their driving habits, reducing fuel consumption and maintenance costs.

- Telematics: Telematics refers to the use of GPS and wireless technology to remotely monitor vehicles and equipment. Forklifts equipped with telematics can be tracked in real-time, providing managers with valuable insights into their operations. This technology can be used to optimize forklift usage, reduce downtime, and improve safety.

- Augmented Reality: Augmented reality technology is being used to improve forklift operator practice. Using AR headsets, trainees can simulate driving a forklift in a virtual environment, allowing them to practice driving and handling techniques in a safe, controlled setting. While this technology is newer and more expensive, there’s an opportunity for further advancements to bring costs down.

These are just a few examples of how forklift technology is evolving. As new advancements continue to emerge, the forklift industry will continue to transform, improving safety, efficiency, and productivity in the workplace.

It’s clear that forklifts themselves have improved significantly with the advancement of technology, but what about training? Let’s dive deeper into that below.

How Forklift Training Has Advanced

In the past, becoming a certified forklift operator required attending a physical training course. However, advancements in technology have made it possible to become certified online, from the comfort of your own home. Here’s how this new trend is making forklift training more accessible:

Convenience: Online forklift training offers a level of convenience that traditional training does not. Learners can complete the coursework on their own schedule, from any location with an internet connection. This flexibility is especially beneficial for individuals with busy schedules or those who live far away from training centers.

Cost-effective: Online forklift training is typically less expensive than traditional training programs. This is because there are no costs associated with renting a physical classroom or hiring an instructor. Additionally, learners can save on travel expenses, as they can complete the coursework from home.

Customization: Online forklift training can be customized to meet the needs of individual learners. This means that learners can focus on the areas where they need the most improvement, rather than sitting through a one-size-fits-all training course. This can result in a more efficient and effective learning experience.

Interactive: Online forklift training can be just as interactive as traditional training programs. Learners can engage in simulations and quizzes, allowing them to practice their skills and receive immediate feedback. This interactive experience can help learners to better retain information and apply it in real-world scenarios.

Accessibility: Online forklift training is more accessible than traditional training programs. Learners with disabilities or mobility issues can complete the coursework from home, without the need to travel to a physical training center. This makes forklift certification more accessible to a wider range of individuals.

In summary, advancements in technology have made it possible to complete forklift training online, offering convenience, cost savings, customization, interactivity, and accessibility. As the trend towards online learning continues to grow, forklift training will become even more accessible to individuals seeking certification in this field.

Get Forklift, MEWP & Fall Protection Certified Today with Liftoff Certifications

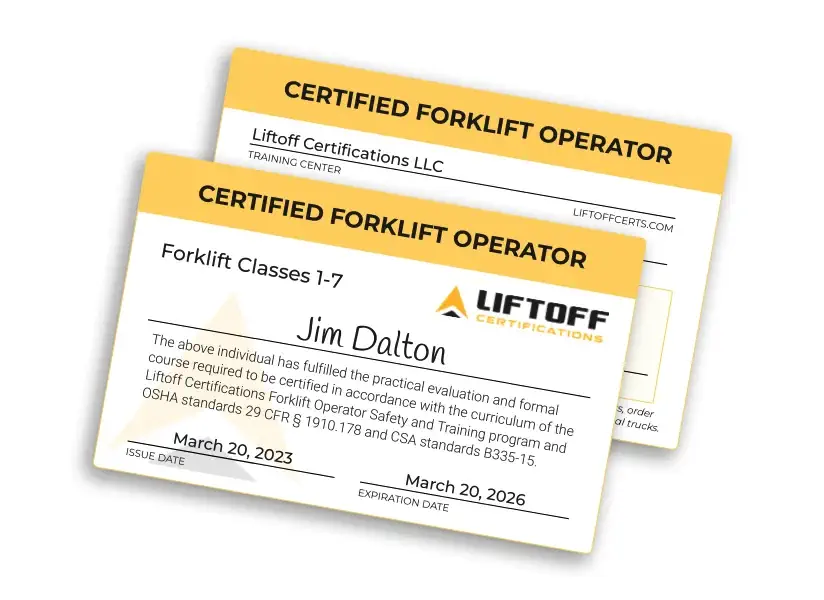

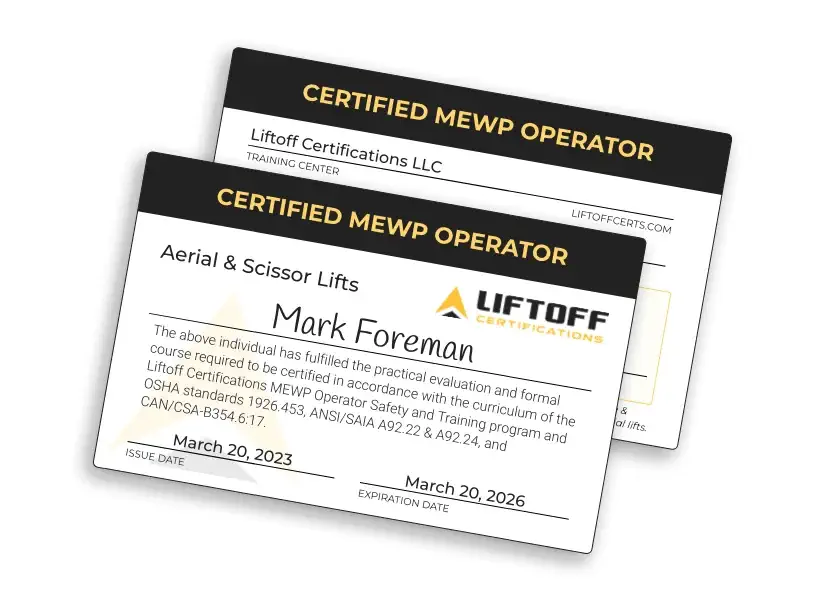

Liftoff Certifications offers some of the industry’s most affordable Forklift Operator, MEWP (Boom & Scissor Lift) Operator, and Fall Protection Certification and Recertification courses and is the gold standard for online OSHA training.

If you are ready to give an online forklift certification or recertification a try, get signed up today for our OSHA Forklift Operator Training.

For our MEWP (Boom & Scissor Lift) training, get signed up today for the OSHA MEWP Operator Training.

And for Fall Protection, get registered for by clicking here for the OSHA Fall Protection Training.

We’ve got you covered with a 100% money back guarantee and we guarantee national acceptance of our OSHA certification.